Innovating

to Zero

Cleaner Operations

Boeing is accelerating improvements in the environmental performance of the company’s operations, as business continues to grow.

Building on the demonstrated performance over the last five years, Boeing is committed to maintaining 2012 levels for greenhouse gas emissions, water use and solid waste to landfill through 2017, even as our business continues to grow. We also are committed to our hazardous waste generation growing at a rate no more than the rate at which our business is expanding.

Increasingly, Boeing is seeking opportunities to incorporate energy conservation technologies and sustainable materials into new building designs as well as to reduce the amount of water used and waste generated by our facilities. Currently,

- Boeing relies on carbon-free hydroelectric and renewable energy sources for nearly half our total electricity consumption.

- Carbon-free hydroelectric energy supplies more than 80 percent of the power for Boeing’s Everett and Seattle facilities in Washington.

- The North Charleston, South Carolina, site is powered by 100 percent renewable energy, sourced from 10 acres (4.05 hectares) of solar panels on the roof of the final assembly building, and coupled with renewable energy credits purchased from the local utility.

- Twenty percent of the power that runs Boeing facilities in Southern California comes from wind energy.

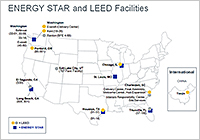

This year Boeing earned the 2014 ENERGY STAR® Partner of the Year Sustained Excellence award from the EPA for leadership in energy conservation. Boeing has won the ENERGY STAR award every year since 2011.

The improvements in Boeing’s operational environmental performance are the result of innovative projects — often led by employee teams — at our facilities across the globe.

LEED GOLD Delivery Center in Everett, Washington

This year, an unprecedented number of commercial airplanes will be delivered to airline customers around the world from the delivery center in Everett, Washington, located next to where the majority of Boeing’s widebody airplanes are built. In April, as the 180,000-square-foot (16,700-square-meter) center celebrated its one-year anniversary, it also received the Leadership in Energy and Environmental Design (LEED) Gold certification from the U.S. Green Building Council.

Characteristics that contributed to LEED Gold certification included lower energy and water use, natural lighting, and the use of recyclable and locally sourced materials, along with the reuse of packing materials.

The delivery and welcome center in South Carolina has also received LEED Gold certification, and work is underway to expand the delivery center in Renton, Washington, which also will meet Boeing’s LEED Silver standard. The new delivery center also will more than double the space that will be available for customers and Boeing groups supporting the increasing 737 commercial airplane deliveries.

Boeing designs all new construction and major renovation projects to meet a LEED Silver rating or higher. More than 60 percent of all Boeing LEED-certified buildings have received Gold-level certification.

Video:

Everett Delivery Center: A day in the making

Watch a time-lapse video of a day at the Everett Delivery Center, which is LEED Gold certified by the U.S. Green Building Council.(Boeing image)

Solar-powered Paint Facility in Salt Lake City

Located on the roof of the paint facility at Boeing’s Salt Lake City site, thousands of solar tubes collect energy from the sun, making it the first Boeing paint facility to be partially heated by solar energy.

The 35,000-square-foot (3,251-square-meter) LEED Silver-certified building is used for painting the horizontal stabilizer of Boeing’s 787-9 airplane. To receive the LEED Silver certification, the building was designed to include numerous large windows, which are not commonly used in paint facilities; a rainwater collection system; recycled and salvaged building materials; and enhanced heating and air controls. But it's the 3,600 rooftop solar tubes that help heat water for the paint curing process that make the building unique.

Through the use of the solar tubes, energy consumption is expected to be reduced by 7 percent for the curing process. Boeing’s Salt Lake facility is also one of Boeing’s six zero-solid-waste-to-landfill sites.

Boeing also uses solar energy to power its facility in North Charleston, South Carolina. The thin-film solar installation on the final assembly building roof has a peak capacity of 2.6 megawatts, and produces enough energy to power 250 residential homes. It is also one of the largest solar installations of its type in the southeastern United States.

Brighter, Energy-efficient Parking Lots in Winnipeg, Manitoba, Canada

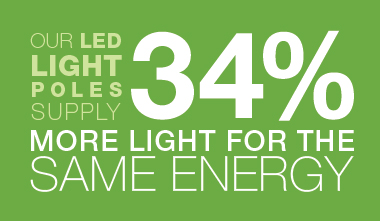

Reducing energy use is high priority for the Boeing Canada facility in Winnipeg. With the construction of a new parking lot and entrance to the site in 2013, the Winnipeg team took advantage of the rapid improvements in light-emitting diode (LED) technology to upgrade some of its lighting features. Providing 34 percent more coverage, only 45 LED light fixtures were necessary to cover the 700-stall, 272,575-square-foot (25,323-square-meter) lot, reducing the number of light fixtures required by about half. Lower maintenance costs, longer life and superior energy efficiency all translate into lower energy requirements and costs.

ISO 14001

Third-party certification to the internationally recognized ISO 14001 environmental management standard has strengthened our companywide focus on continuous improvement and enabled a common way of managing environmental processes across the company. More than 50 sites around the world, including all major manufacturing facilities, are certified to ISO 14001 standards. In 2013, four of our facilities in Australia — Brisbane, Humpty Doo, Riverina, and Townsville — all received certification for the first time. Boeing’s distribution centers and many joint ventures and suppliers are also ISO 14001 certified.