Designing

the Future

Cleaner Products

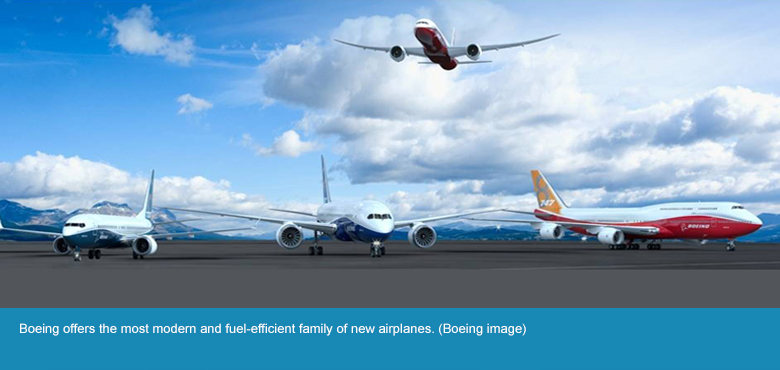

Boeing builds and delivers the world’s most modern and fuel-efficient fleet of airplanes. This brings enormous value for our commercial and defense customers by finding new opportunities for efficiencies that cut their fuel costs and reduce greenhouse gas emissions while improving the environmental performance of the aerospace industry. With the launch of the 777X and the 787-10 in 2013, Boeing advances the world’s most efficient and flexible twin-aisle family.

787 Dreamliner

The Boeing 787 DreamlinerTM is the most advanced and efficient commercial airplane in its class, setting new standards for environmental performance and passenger comfort. Composite materials, advanced engines and a new innovative wing design all help the 787 reduce fuel consumption and CO2 emissions.

The third and longest member of the 787 family — the 787-10 — will fly more than 90 percent of the world's twin-aisle routes at a whole new level of efficiency. The airplane's operating economics are unmatched: 25 percent better fuel use and emissions compared to airplanes of its size today and more than 10 percent better than anything being offered by the competition. First delivery of the 787-9 is scheduled for 2014, and the 787-10 is targeted for 2018.

Video:

787-9: Innovation Evolution

Learn more »

777X

In the fall of 2013, Boeing launched the 777X with agreements for 259 airplanes, representing the largest product launch in commercial jetliner history by dollar value. With all-new composite wings and all-new GE9X engines, the 777X will be the largest and most efficient twin-engine jet in the world — and 12 percent more fuel-efficient than its competitor.

The airplane's folding, raked wingtip and optimized span will contribute significantly to this greater efficiency and fuel savings.

747-8

The 747-8 is 16 percent more fuel-efficient than its predecessor and delivers more passengers, more cargo and more range with lower emissions and noise. In 2013, Boeing delivered the first 747-8 with performance-improved GEnx-2B engines as part of the airplane’s Performance Improvement Package, or PIP. The two other components of the PIP program include flight management computer software upgrades and reactivation of the horizontal stabilizer tank fuel system on the 747-8 Intercontinental. Through the PIP program, 747-8 customers will use roughly 30 fewer trucks of fuel per airplane per year, a 1.8 percent improvement.

737 MAX

Boeing’s newest family of single-aisle airplanes — 737 MAX 7, 737 MAX 8 and 737 MAX 9 — will build on the Next-Generation 737’s popularity and reliability while delivering customers unsurpassed fuel efficiency in the single-aisle market.

The 737 MAX will deliver the significant savings in fuel that airlines require for the future. The 737 MAX improves fuel efficiency and CO2 emissions by an additional 14 percent over today's most fuel-efficient Next-Generation 737s and 20 percent more fuel efficient than the first Next-Generation 737s to enter service. Design updates, including Boeing’s Advanced Technology winglet, also will further optimize the 737 MAX performance, especially on longer-range missions.

When compared to a fleet of 100 of today's most fuel-efficient airplanes, this new model will be approximately 8 percent more fuel-efficient per seat than the competition, emit 305,040 fewer tons of CO2 and save more than 215 million pounds of fuel per year, which translates into more than $112 million in cost savings.

The 737 MAX will incorporate the latest quiet-engine technology to reduce the operational noise footprint of the airplane by up to 40 percent.

Development of the 737 MAX is on schedule with firm configuration of the airplane achieved in July 2013. First flight is scheduled in 2016 with deliveries to customers beginning in 2017.

The Next-Generation 737 program also continuously evaluates and incorporates value-added technologies and design innovations to improve performance and capabilities. Recent offerings include short-field performance enhancements to increase payload capacity and to reduce takeoff and landing field length; and carbon brakes to reduce weight for improved airplane operating economics.

All-electric Propulsion Satellite

Boeing is building the world’s first all-electric propulsion satellites. The all-electric propulsion design of the 702SP (small platform) satellites gives customers new flexibility and next-generation technology for increased performance, more affordable launch options and the ability to nearly double payload capacity.

The 702SP relies exclusively on xenon (an inert, nonhazardous gas) for its propulsion system and builds on the success of the 702HP (high power) spacecraft hybrid propulsion technology, which uses a combination of chemical bipropellant and xenon-ion propulsion.

Production on the first 702SP satellites began in 2013, and testing, verification and assembly of the primary structures was completed in early 2014.

Chrome-free Defense Solutions

Boeing, along with its customers, is committed to reducing the use of hazardous materials in the manufacture and maintenance of its products. The challenge is to find alternatives that meet strict safety, aircraft integrity and regulatory requirements.

Currently, Boeing is testing and using new solutions such as hexavalent chrome-free primers for its AH-64 Apache helicopter, the

V-22 Osprey, F/A-18E/F Super Hornet and

EA-18G Growler and P-8 programs. The new coatings meet strict requirements while reducing the use of hazardous chemicals in the manufacturing process.

Boeing is an industry leader in developing alternatives to paints and primers that contain hexavalent chromium, a heavy metal that resists aircraft corrosion but also can be toxic to people and the environment.

Boeing, the U.S. Navy and other customers are exploring other alternatives and are implementing lean manufacturing techniques to help optimize workflow and reduce waste.