Inspiring Global Collaboration

Engaging the Industry

Map note: Guam: Boeing and NRG Energy are building the island nation’s first solar power plant.

Boeing is leading global collaboration, finding solutions for complex environmental challenges.

Boeing works with organizations, institutions, customers and governments around the world to drive environmental improvements throughout our industry and across the globe. In addition, Boeing employees and executives work with local, national and international environmental organizations in a number of voluntary and professional capacities.

Sustainable Aviation Biofuel

As part of our core commitment to protect the environment and support the long-term sustainable growth of aviation, Boeing is the industry leader in global efforts to develop and commercialize sustainable aviation biofuel. A new sustainable jet fuel is essential to reduce commercial aviation’s carbon emissions, reduce our industry’s reliance on fossil fuel, and reach our industry’s goal of carbon-neutral growth from 2020.

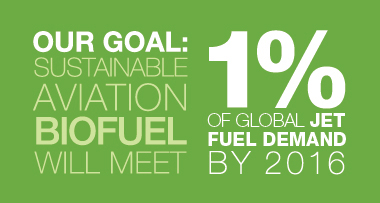

Boeing is focused on so-called “drop-in” sustainable biofuel, which can be blended directly with the traditional petroleum jet fuel supply with no changes to airplanes, engines or fueling infrastructure. Boeing’s goal is that by 2016, sustainable biofuel will address 1 percent of global jet fuel demand, equivalent to 600 million gallons (2,271.25 million liters) of jet fuel. One percent often represents the tipping point to show proof of concept for a new technology, leading to increased investment and more rapid market expansion.

Sustainable aviation biofuel can be made from organic sources like plants or algae, and from bio-based inedible feedstocks such as waste cooking oil, animal fat or municipal solid waste.

Boeing is focused on alternative fuel development that meets sustainability criteria. This includes working with feedstocks that do not adversely affect local food supplies, freshwater supplies or land use policies. Many Boeing biofuel projects also encourage social and economic development, such as new opportunities for farmers to use marginal land for sustainable aviation biofuel crop production.

Biofuel efforts supported by Boeing use principles established by the international Roundtable on Sustainable Biomaterials (RSB). These sustainability principles address greenhouse gas emissions, local food security, conservation, soil, water, air, and technology, inputs and waste management. Boeing currently has active biofuel development projects on six continents, including in the United States, Europe, China, Japan, Middle East, Southeast Asia, Brazil, Southern Africa and Australia.

Global Approach to Aviation Emissions

Because aviation is a global industry, with airplanes crossing international borders every day, Boeing believes that a global system is needed to address aviation emissions. We advocate that a global emissions framework for aviation can best be achieved through the International Civil Aviation Organization (ICAO), a United Nations organization.

Boeing fully supports the ICAO position on controlling aviation emissions and, along with the rest of the aviation industry, is working toward meeting these commitments.

Working through the ICAO, aviation was the first industry to present a clear plan to the United Nations’ ongoing climate change negotiations. The ICAO calls for global guidelines, including the development of a CO2 standard for aircraft, improvements in air traffic control systems to cut air travel–related emissions by up to 12 percent, and continued efforts to promote the commercialization of sustainable alternative fuels. These efforts all aim to achieve carbon-neutral growth across commercial aviation by 2020 and reduce the footprint after that.

In October 2013, the ICAO General Assembly in Montreal agreed on a road map, aligned with the aviation industry’s position, toward a global market-based approach to climate change. The ICAO agreement, reached by representatives from 191 nations, includes a commitment that, by 2016, the ICAO will develop a program to cut emissions using a market-based measure, most likely through carbon offsetting during which emissions from one source can be counterbalanced by environmental measures elsewhere. A global market-based measure adopted in 2016 would take effect in 2020. Boeing believes that this ICAO agreement represents great progress toward a global approach to aviation emissions, with more steps ahead.

Commercial Aviation Operational Efficiency

As air traffic continues to grow around the world, air navigation and management services must keep pace. Studies have shown that a modernized air traffic management system can improve the efficiency of all airplanes flying by as much as 12 percent, reducing fuel use and greenhouse gas emissions as well as saving time for passengers and aircraft operators. Cutting flight times on a global basis by just one minute per flight would reduce carbon emissions by 4.8 million tons (4.4 million metric tons) annually, according to the International Air Transport Association (IATA).

Boeing advocates for modernization of the global air traffic management system infrastructure and is enabling greater operational efficiency through support and services that provide improved airline operations, such as the Boeing Wind Updates and Direct Routes programs.

Using industry-leading technologies and Boeing-developed algorithms, these services supply airlines with customized real-time wind and temperature information — delivered directly to the aircraft — and real-time information about optimal routings. The data generated by these programs allow for more efficient trajectory prediction during preflight operations and continuous optimization in flight by providing tailored information for flight crews and the aircraft flight management system. Wind Updates data are also individually tailored to the specific aircraft type, regardless of manufacturer, to provide optimal performance. In early 2014, Boeing and Qatar Airways announced a five-year agreement to provide Boeing Wind Updates services for the airline to maximize in-flight operational efficiency.

Video:

Air traffic management improvements combined with advances in aircraft design can significantly reduce fuel consumption and emissions. (Boeing image)

Learn more »

Chemicals and Hazardous Materials

Manufacturing airplanes and defense products is a complex process, involving in some cases millions of parts from around the world; every aircraft must meet strict safety, aircraft airworthiness and regulatory requirements. Increasingly, information about the use of chemicals and hazardous materials contained in products or used in production processes is being required to meet new requirements, such as the European Union regulation of chemicals called REACH (Registration, Evaluation, Authorisation and Restriction of Chemicals).

The International Aerospace Environmental Group (IAEG), of which Boeing was a founding member, is helping the industry meet the growing and expanding requirements. To do this, IAEG is:

- Identifying the materials/substances that are relevant for reporting.

- Developing understanding among the aerospace industry of environmental requirements faced by the world’s supply chain.

- Optimizing collaboration and driving integration of different company requirements, when possible, to create industry solutions.

- Working through its member companies to conduct research to pursue the development and implementation of hazardous chemical alternatives throughout the value stream that meet aerospace performance and safety requirements.

As a result of the collaboration among the aerospace companies, a voluntary greenhouse gas reporting standard has been developed by, and for, the aerospace industry. The organization is also conducting a pilot project and survey with its member companies and numerous aerospace suppliers to develop a standard for chemical reporting for the industry. This work will ensure that the proposed voluntary standard is effectively meeting the needs of aerospace.

These new voluntary standards help improve efficiencies by eliminating the need for each company to develop its own system. IAEG membership has doubled since the group formally was established in June 2011, now representing more than 50 percent of the world’s total aerospace market.

Finding Alternative Solutions

Through collaboration with groups such as the National Center for Manufacturing Sciences (NCMS) Consortium, Boeing is supporting industry efforts to find alternatives for hazardous materials used in manufacturing and operating aircraft. Recently, Faraday Technology Inc. in Clayton, Ohio, developed a new technology with funding from Boeing, the EPA and NCMS to reduce the amount of hazardous chemicals in the manufacture of commercial and military aircraft. The work received a Presidential Green Chemistry Challenge Award from the EPA.

The new technology is a major improvement in the process that currently requires the use of hexavalent chromium in the coating that prevents wear and extends the service life of aircraft parts, including landing gear and hydraulic system components. The improved coating process will enable manufacturers to use trivalent chromium, a less toxic material, which delivers equal or improved performance.

The EPA estimates that use of Faraday’s new coating process could eliminate 13 million pounds (5.9 million kilograms) of hexavalent chromium waste each year in the United States and as much as 300 million pounds (136 million kilograms) worldwide.

Boeing is also leading the industry to accelerate the development of an industrywide non-Halon solution for propulsion systems fire protection through a new industry research consortium. We also are working to establish a time frame for developing cargo Halon replacements for the ICAO.