Virtual reality has real-world environmental benefits

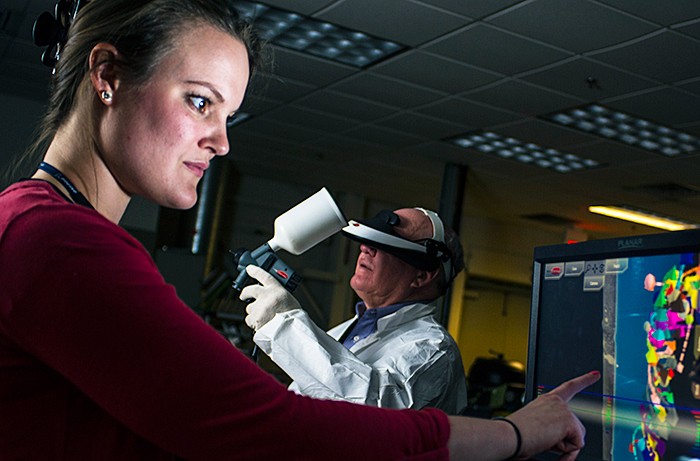

Engineers Emily Sprik and Brian Boutilier demonstrate equipment that creates a virtual reality painting experience designed to improve the skills and efficiency of Boeing painters. (Boeing photo)

With fluid body movements and a hand-held spray gun, engineer Brian Boutilier might look like he’s pretending to paint an unseen Boeing aircraft. But with a high-tech headset, computer and 3-D technology, Boutilier has immersed himself in a virtual reality where he sees and is learning how to correctly paint a Chinook helicopter.

“This is as close as you can get to hands-on training in a classroom. It’s realistic; when you pull the trigger it sounds like a spray gun,” said Boutilier, a research engineer at Boeing’s Philadelphia site, home to the Chinook and V-22 tiltrotor aircraft.

Boutilier and teammate engineer Emily Sprik helped develop a training program for aircraft painters that uses advanced technology to create a virtual reality painting experience with real-world benefits for the company and the environment.

“Training in a ‘virtual’ paint hangar allows painters to improve their skills and efficiency without wasting paint,” Sprik said. “Reducing waste and boosting a painter’s efficiency means less paint goes into the air during painting. And it helps reduce the amount of hazardous material on the aircraft and in the environment.”

Sprik and Boutilier discovered the virtual reality training equipment several years ago when they were asked by the site’s painting group to set up a hands-on remedial training program for painters who wanted to improve their skills.

Sprik said the technology is a one-stop shop for training. “It gives you immediate feedback on your skills. We can program the system to mimic an actual project a painter would have on an aircraft,” she said.

“It helps a painter improve movement and muscle memory. And the system helps a painter avoid overspray and using too much paint, which is a real benefit for the environment.”

The site’s painters generally like the virtual reality experience but Sprik also noticed a generational difference in the painters’ first reaction to the equipment. “The younger painters usually have more experience with new technology and video games and were comfortable with the equipment,” she said.

“But once the more experienced painters tried the equipment, they could see the benefits.”

The Everett, Washington, commercial airplane factory now also uses the virtual reality painting technology, and the equipment is being studied for possible use at other Boeing sites, Sprik said.

Boutilier, who has worked at Boeing for 46 years, said it’s encouraging to see younger workers taking up new technology. Sprik agrees. “To me it’s very important that Boeing is on the cutting edge of technology development. It’s helping us improve our environmental footprint and worker safety,” she said.